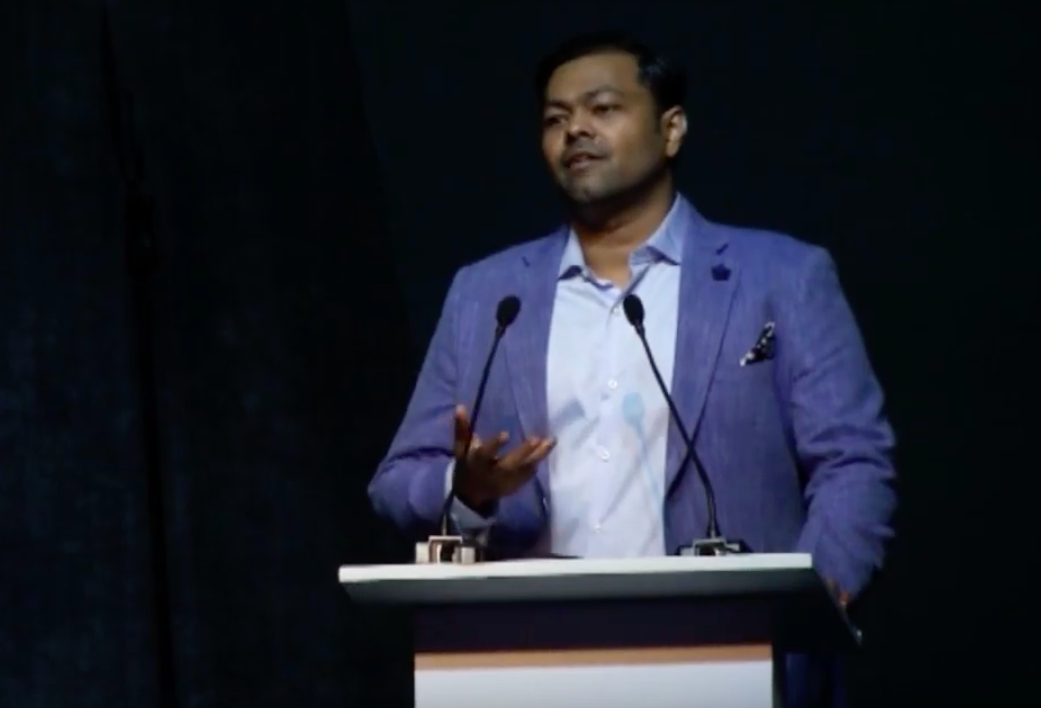

“Cradle to cradle developments and eco-initiatives will provide a wealth of opportunities for my country”

The initiatives that Mostafiz has undertaken have always been driven by his principles and desire to make things better, rather than making them for commercial gain.

Since the resource of mother earth is limited, Mostafiz Uddin believes that a business is only sustainable when it produces more with less waste. So, for promoting recycling and reusing of materials Mostafiz Uddin started Bangladesh Circular Economy Summit in 2023.

To this end, Mostafiz Uddin also established the Recycle Exchange the first ever model textile sorting center in Dhaka. The Recycle Exchange aims to promote a circular fiber-to-fiber economy by fostering industry innovation, from efficient sorting to advanced recycling practices.

At his factory, DENIM EXPERT LTD. he has pioneered the way to achieving certifications including WRAP, SEDEX, BSCI and was one of the first in Bangladesh country to be accredited the ISO 9001: 2008 and ISO 14001: 2004 certificates.

In order to achieve this and to ensure that the highest sustainable standards are maintained, Mostafiz has formed an autonomous, in-house compliance management team that oversees all aspects of transparent, sustainable, responsible production at the factory.

Today DENIM EXPERT LTD consumes an average of 32 litres of water per jean manufactured, where other factories consume 60 litres and more and the company is looking at methods to reduce this water usage further. The factory has installed a rainwater harvesting system and an ultra-efficient effluent treatment plant (ETP) with the saved and treated water being used in the factory’s laundry facility and washrooms.

Mostafiz recently launched, through DENIM EXPERT LTD. their first circular fashion collection under the brand name CIRCLE. The vision for the development came from Mostafiz’s experiences at the 2018 Copenhagen summit, and the collection was produced in-house by the less able bodied and transgender employees of Denim Expert Ltd.

All of the product in the range is designed so that its sub-components can be disassembled or separated to facilitate repair, remake, reuse and eventually, at the end of the product life cycle, the recycling of the material.

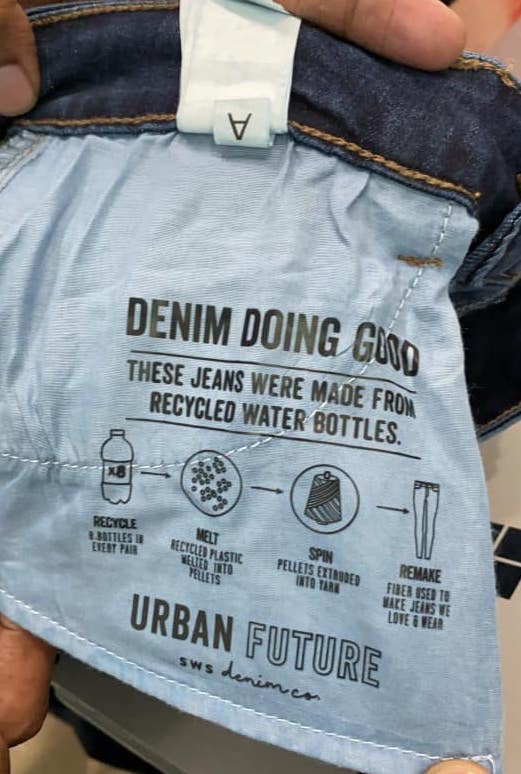

DENIM EXPERT LTD PRODUCES JEANS MADE FROM RECYCLED BOTTLES.

For their latest denim developments and, under the guidance of Mostafiz, the Denim Expert Ltd. development team have made a concerted effort to focus on the use of recycled materials for their Spring/ Summer 2021 collection.

After extensive research into the finest denims available, the team have concocted a range of product using REPREVE® polyester fibres, made from recycled plastic bottles, drastically reducing the environmental impact of the product made from the selected fabrics.

For the 10th edition of BANGALDESH DENIM EXPO, Mostafiz promoted the theme of CIRCULARITY, highlighting the needs of the apparel industry to address the waste that the industry creates and to consider alternative circular business models, rather than the accepted industry norms.

To further strengthen the importance of the CIRCULARITY message and, as Mostafiz strives to highlight new approaches in all his business activities, the entire exhibitor booth concept was made from recycled cardboard tubes from local garment factories and fabric mills and reclaimed wood materials.